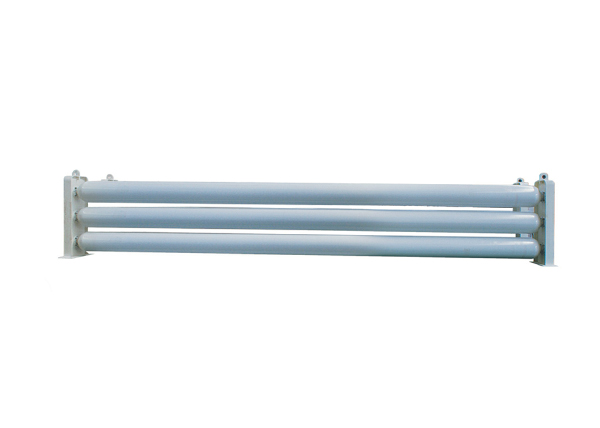

In the early stage of the development of CNG filling stations, the main equipment configuration was only compressors, but no gas storage tanks. After years of exploration practice, people have gradually realized that equipping the compressor system with an appropriate gas cylinder set ( buffer tank) can significantly improve the technical performance of the stability reliability of the filling system greatly improve the system's work. effectiveness. CNG refueling stations are designed to achieve the same filling rate as petrol refueling stations (the rate, the demand for refueling capacity (flow) is greater than the compressor's gas supply capacity, also to avoid the need for refueling vehicles (the interval is uncertain) Causes the compressor to start frequently cause damage to the compressor equipment. Generally, the compressed gas is temporarily stored in the container, that is, the compressed high-pressure natural gas is charged into the gas cylinder group for use.

① CNG compressors are mostly reciprocating compressors. The pressure of the output gas fluctuates greatly when the station gas storage cylinder group is working. When the gas storage cylinder group is added, it can buffer the shock airflow of the compressor ensure the output airflow. stability.

② Increasing the capacity of the gas storage tank group can appropriately reduce the compressor discharge volume without changing the gas supply capacity of the filling station, reduce the cost of the filling station. Foreign experience shows that its cost is about 30% lower than that of a direct-filling gas station without a gas cylinder.